The different grades of concrete are M5 M75 M10 M15 M20 M25. Determine the mean target strength ft from the specified characteristic compressive strength at 28-day fck and the level of quality control.

Mix Design Method According To Is Code Recommended Guidelines Lceted Lceted Institute For Civil Engineers

You need a 5000-psi mix with a 5 air content and you need to be able to strip the products from the forms in 15 hours.

. Data for mix design The following basic data are required to be specified for design a concrete mix Characteristic Compressive strength only a few specified proportions of test results are expected to fall of concrete at 28 days fck Degree of workability desired Limitation on waterCement Ratio with the minimum cement to ensure adequate durability. 1Required ratios of each component. A concrete mix is a combination of five major elements in various proportions.

The separation of water or water-cement mixture from the freshly mixed concrete is known as bleeding. Vicat Apparatus is used for. Here are several common questions.

Where S standard deviation in Nmm 2 4 as per table -1 of IS 10262- 2009. Differentiate dry process and wet process of manufacturing cement. What are all the raw materials of the cement.

List out various tests on Coarse Aggregate. List out various tests on Bitumen. Mix Design Procedures ACI Mix Design Relationship between watercement ratio and compressive strength of concrete 28-day Compressive Non-AE AE Strength psi 2000 082 074 3000 068 059 4000 057 048 5000 048 040 6000 041 032 7000 033---Mix Design Procedures ACI Mix Design 6.

Initial Setting Time of Cement. Aggregates with good strength size specific gravity and free of organic material are used. The continuous strain which the concrete undergoes due to application of external loads is called.

Join millions of learners from around the world already learning on Udemy. Concrete technology viva questions. Moisture in aggregate in concrete mix design.

Advantages of Concrete Mix Design. At Concrete Supply Co we sleep better at night knowing our end-to-end ready mix concrete solution meets the highest quality performance in concrete and our integrity in doing so is unparalleled. Why Concrete Cover is provided for reinforcement.

We offer a guide to help you find your perfect read mix. Choose from many topics skill levels and languages. Abs Volume 667 315 X 624 Cement 667 315 339-Total Cementious 667 Miller Stone 1590 26 980 Evert Sand 1242 265 751 Water 300 1 481 1590 260 X 624 1242 265 X 624 481 Air 55 1485 Total 3799 2700 w cm 045 Unit Wt.

To know the Concrete Mix Design follow below-Mix Design M Cement. 620 x 0400 248 Lbs of water. A good general rule to use is the rule of 6s.

Procedure for Concrete Mix Design of M25 Concrete Step 1 Determination Of Target Strength Himsworth constant for 5 risk factor is 165. The Concrete mix ratio for M20 grade of concrete is 1153 that mean 1 part of cement 15 part of sand fine aggregate and 3 parts of aggregate crushed stone in volume and then batched for mixing. Good concrete can be obtained by using a wide variety of mix proportions if proper mix design procedures are used.

What are some best practices when it comes to concrete slab construction. Procedure for Concrete Mix Design as per IS 456. A 3 change in water content can cause a variety of 20mm in a slump and would generally affect the concrete strength by 2 Nmm 2.

What do you know about NDT. A quality concrete mix design is crucial for successful construction. 3 Standard Concrete Design- Standard concrete mixratio is based on IS Code 456-2000 concrete mix.

In this case standard deviation is taken from IS456 against M 20 is 40. You typically use around 1560 pounds of coarse aggregate. Historically for similar mixes youve used 555 pounds of cement and 120 pounds of fly ash per cubic yard of concrete.

Additional elements such as pozzolanic materials and chemical admixtures can also be incorporated into the mix to give it certain desirable properties. A list of the top 175 civil engineering interview questions pdf and answers to ensure your next interview is a success. The properties of the resulting mixture in proportion to each component such as cement coarse aggregate fine aggregate water are required.

Water weight 32 gal x 833 267 Lbs wc 267 517 0516. List out various tests on Cement. But if you order a 6-sack mix all that tells you is how much.

The moisture in the sand can cause a variation of as much as 20 in the quantities of materials batched by volume. The developments in the field of concrete mix design gave compressive strength ranging between _____ a 30-70 b 70-100 c 35-45 d 30-80 Answer. Constructing a flawless concrete slab doesnt require knowing all the secrets of the universe but it helps if you have some basic understanding.

How do you measure the volume of concrete. While a concrete mix design is a process of selecting ingredients. When most contractors think about concrete mix designif they think about it at allthe first thing that comes to mind is bags or sacks In the old days when most concrete was mixed on site cement was purchased in bags.

Concrete Technology LAB VIVA Questions - 1. 14072 Basic Concrete Mix Design Materials Pounds of. Calculation of cement content-- Once the water.

A minimum cement content of 6 bags per cubic yard of concrete A maximum water content of 6 gallons per bag of cement. 250 Concrete Technology Interview Questions and Answers Question1. Basic Concrete Mix Design Materials Pounds of material SG.

Invariably there are many answers to this question. What are all the types of cement. Wc 045 and water content for mix 1974 kgm 3.

Define batching what are all the methods of batching. F target f ck 165 x S 25 165 x 40 316 Nmm 2. Example 4 Determine wc given a mix design with 32 gallons of water and 517 Lbs of cement per yd.

It has been separated into different mix ratios of concrete ie quantity of cement sand and aggregates for different grades of concrete. Weight of coarse aggregate 0664 x 0568 x 284 x 1000 107111 kgm 3. List out various equipment used in NDT.

What are recommended mix proportions for good concrete. Prestressed Concrete Structures Multiple Choice Questions on High Strength Concrete. Slump of concrete mix design.

Cement content for mix 1974045 4387 kgm 3. Dry Rodded Unit Weight. F t f ck 165 S where S is the standard deviation obtained from the Table of approximate contents given after the design mix.

Write notes on steam curing. A bag is 94 pounds of cement or about 1 cubic foot. List out various tests on Fine Aggregate.

Cement water coarse aggregates fine aggregates ie. Dry rodded unit weight is sometimes called bulk or loose unit weight. Mix Design Procedure in 8 Steps ACI MethodTables.

Ad Find the right instructor for you. Volume aggregate in total volume of concrete 1 4387 315 x 1000 19741000 0664 m 3.

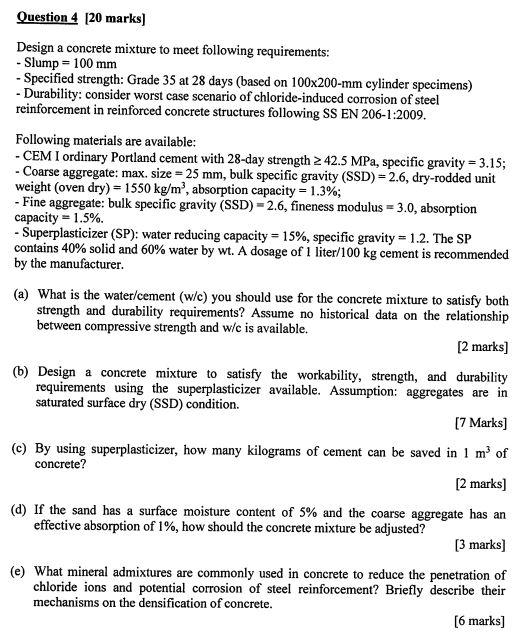

Solved Question 4 20 Marks Design A Concrete Mixture To Chegg Com

20 Civil Engineering Standard Datas Interview Questions Grade Of Concrete Concrete Mix Design Civil Engineering

Questions Frequently Ask About Concrete In An Interview Pdf Ratio Concrete

Top Civil Engineering Interview Questions And Answers

Top 250 Concrete Technology Interview Questions And Answers 22 March 2022 Concrete Technology Interview Questions Wisdom Jobs India

Solved The Following Data Is Taken From The Building Chegg Com

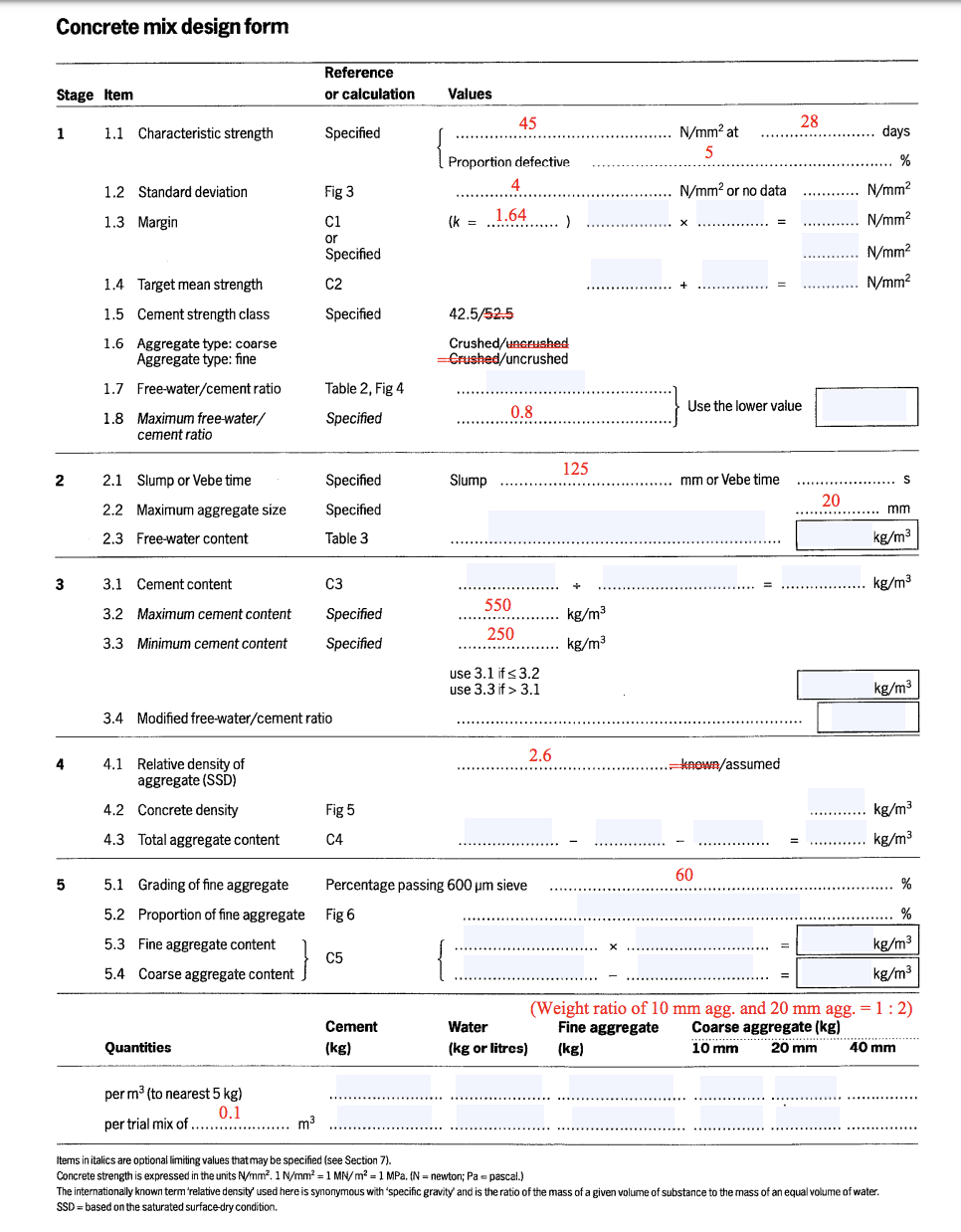

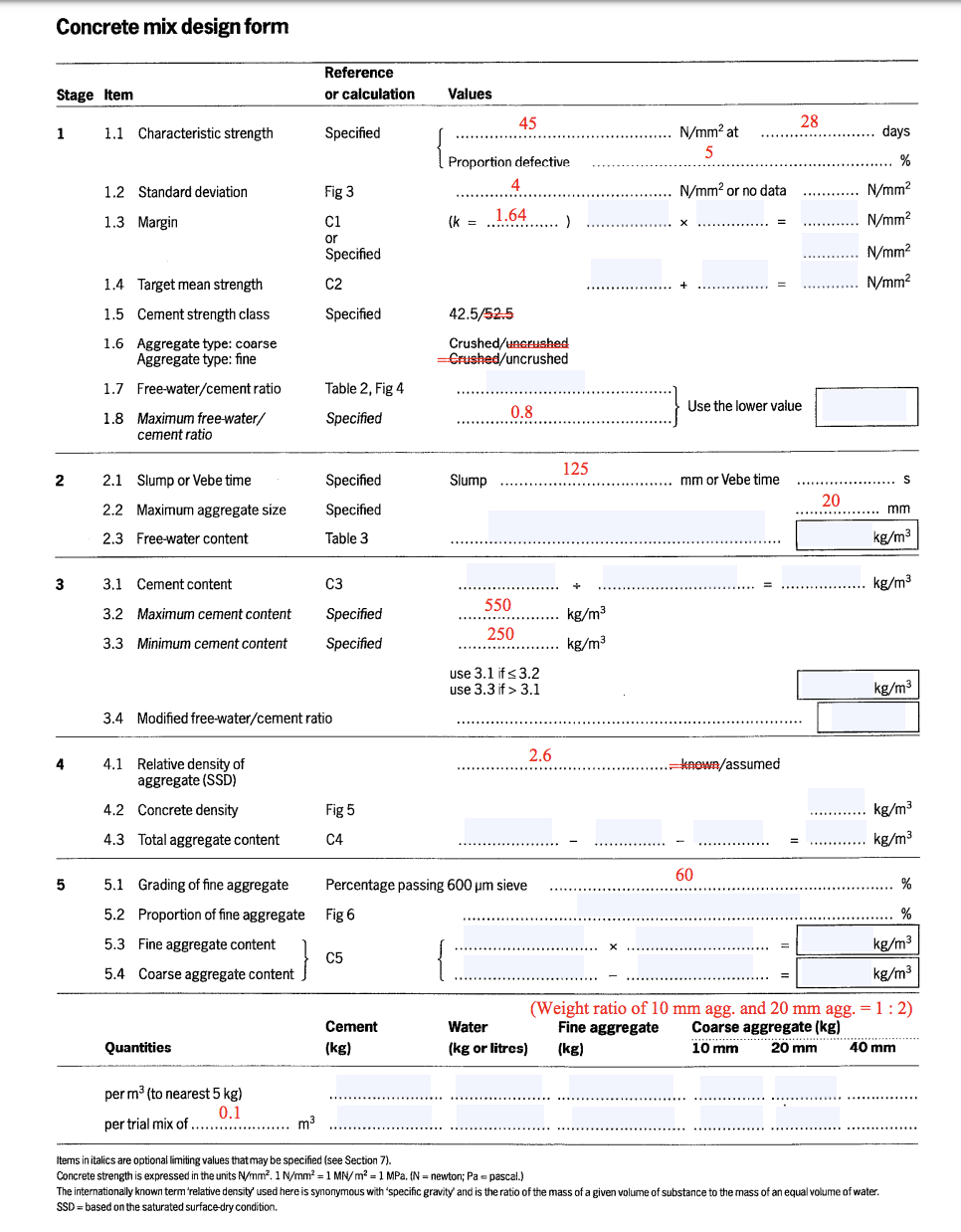

Solved Concrete Mix Design Form Reference Or Calculation Chegg Com

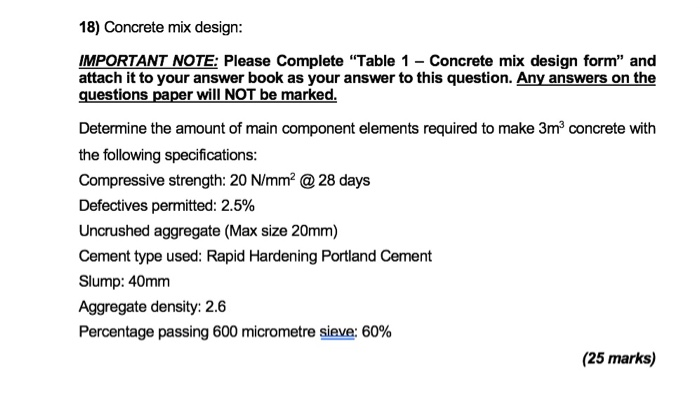

Solved 18 Concrete Mix Design Important Note Please Chegg Com

0 comments

Post a Comment